Understanding proper angle valve maintenance is essential for ensuring optimal performance and longevity in industrial piping systems. These critical components serve as flow control devices that regulate fluid movement through pipelines, making their reliable operation vital for system efficiency. Regular maintenance practices can prevent costly downtime, extend service life, and maintain precise flow control capabilities. Industrial facilities that implement comprehensive angle valve maintenance programs typically experience fewer emergency repairs and improved overall system reliability.

Essential Components of Angle Valve Systems

Understanding Valve Body Construction

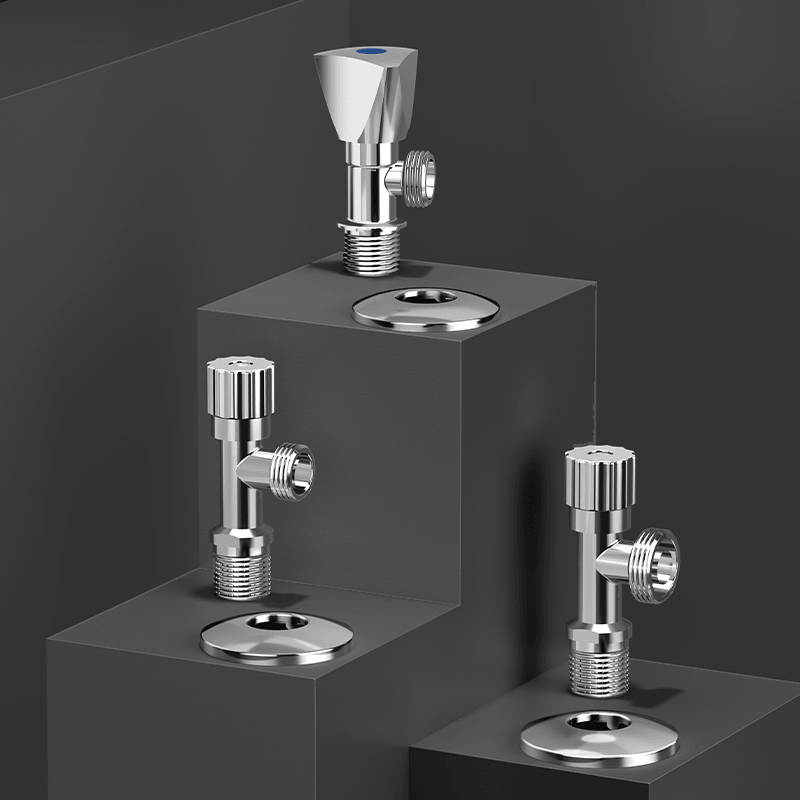

The angle valve body forms the primary housing that contains all internal components and determines flow characteristics. Manufacturing materials typically include stainless steel, brass, or specialized alloys depending on application requirements. Body design features influence pressure ratings, temperature tolerance, and chemical compatibility with process fluids. Proper inspection of the valve body during maintenance reveals potential issues like corrosion, erosion, or structural damage that could compromise system integrity.

Surface preparation and protective coatings play crucial roles in preventing premature deterioration of angle valve bodies. Regular visual inspections should focus on identifying signs of external corrosion, particularly around threaded connections and flange surfaces. Internal inspection through non-destructive testing methods can reveal wall thickness reduction or material degradation that might not be visible externally.

Stem and Actuator Mechanisms

The stem assembly connects the external actuator to the internal flow control element, making it a critical component for angle valve operation. Proper stem alignment ensures smooth operation and prevents binding that could lead to excessive wear or operational failures. Lubrication of stem threads and bearing surfaces should follow manufacturer specifications to maintain optimal performance characteristics.

Actuator systems vary from manual handwheels to pneumatic or electric operators, each requiring specific maintenance approaches. Regular calibration of automated actuators ensures accurate positioning and response times that meet process control requirements. Preventive maintenance schedules should address actuator lubrication, electrical connections, and pneumatic supply systems as applicable.

Routine Inspection Procedures

Visual Assessment Techniques

Systematic visual inspection forms the foundation of effective angle valve maintenance programs. External examination should include checking for fluid leaks, corrosion patterns, and proper mounting alignment. Documentation of observed conditions provides valuable trend data for predicting maintenance needs and scheduling component replacements.

Internal components require periodic inspection through disassembly or specialized inspection techniques. Endoscopic examination allows assessment of seat surfaces, disc condition, and internal corrosion without complete valve removal. These inspections help identify wear patterns and contamination that could affect performance before they cause operational problems.

Performance Testing Methods

Functional testing verifies that angle valve performance meets operational specifications under various operating conditions. Flow rate measurements at different valve positions help identify internal wear or obstruction that might not be visible during visual inspection. Pressure drop testing across the valve reveals information about internal condition and flow characteristics.

Leak testing procedures ensure that closed angle valve positions provide adequate shutoff capability. Seat leakage testing should follow industry standards and consider acceptable leakage rates for specific applications. Regular documentation of test results helps establish performance trends and optimize maintenance intervals.

Preventive Maintenance Strategies

Lubrication Management

Proper lubrication significantly extends angle valve service life and ensures smooth operation under all conditions. Lubricant selection must consider operating temperature, pressure, and chemical compatibility with process fluids. Over-lubrication can attract contaminants and cause seal damage, while insufficient lubrication leads to premature wear and binding.

Lubrication schedules should be based on operating frequency, environmental conditions, and manufacturer recommendations. High-cycle applications require more frequent lubrication than intermittent service valves. Temperature extremes and corrosive environments may necessitate specialized lubricants and modified maintenance intervals.

Seal and Gasket Replacement

Sealing elements in angle valve assemblies require periodic replacement to maintain leak-tight operation. Material compatibility with process fluids determines seal selection and replacement frequency. Temperature cycling, pressure variations, and chemical exposure all contribute to seal degradation over time.

Replacement procedures must ensure proper installation torque and alignment to prevent premature failure. Seal groove condition should be inspected during replacement, as damaged grooves can cause new seals to fail prematurely. Inventory management of critical seal components helps minimize downtime during maintenance activities.

Troubleshooting Common Issues

Identifying Operation Problems

Operational problems with angle valve systems often manifest as difficulty in opening or closing, irregular flow control, or excessive operating force requirements. These symptoms can indicate internal wear, contamination, or misalignment that requires corrective action. Systematic troubleshooting approaches help identify root causes and determine appropriate repair strategies.

Binding or sticking during operation typically results from inadequate lubrication, corrosion products, or foreign material contamination. Temperature effects can cause thermal binding in applications with significant temperature variations. Proper diagnosis requires understanding of operating conditions and system history.

Addressing Leakage Issues

External leakage around stem packing or body joints compromises system integrity and may create safety concerns. Packing adjustment or replacement often resolves minor stem leaks without complete valve disassembly. Body joint leakage may require gasket replacement or flange surface refinishing to restore proper sealing.

Internal leakage through the seat area affects process control and energy efficiency in many applications. Seat refurbishment or component replacement may be necessary to restore proper shutoff capability. Cost-benefit analysis helps determine whether repair or replacement provides the most economical solution for individual angle valve units.

Advanced Maintenance Techniques

Predictive Monitoring Systems

Modern angle valve maintenance programs increasingly incorporate predictive monitoring technologies to optimize maintenance timing and reduce unexpected failures. Vibration analysis, acoustic monitoring, and thermal imaging provide early warning of developing problems before they cause operational disruptions. These technologies help transition from time-based to condition-based maintenance strategies.

Data collection and analysis systems enable trending of valve performance parameters over time. Statistical analysis of operational data helps identify patterns that predict maintenance needs and optimize component replacement schedules. Integration with plant maintenance management systems facilitates coordination of maintenance activities and resource allocation.

Refurbishment and Upgrade Options

Major refurbishment projects can restore angle valve performance to original specifications while incorporating design improvements. Upgraded materials, improved sealing systems, and enhanced actuator technologies can extend service life and improve reliability. Economic analysis should compare refurbishment costs with replacement options to determine optimal strategies.

Technology upgrades during maintenance shutdowns can improve automation capabilities and integration with plant control systems. Smart valve technologies provide enhanced monitoring and diagnostic capabilities that support predictive maintenance programs. These improvements often justify higher initial costs through reduced operating expenses and improved reliability.

Safety Considerations in Maintenance

Lockout and Isolation Procedures

Safe maintenance practices for angle valve systems require proper isolation and energy control procedures. Process isolation must consider upstream and downstream conditions, potential stored energy, and residual fluids that could create hazards. Multiple isolation points may be necessary to ensure complete safety during maintenance activities.

Lockout/tagout procedures must address all energy sources including process pressure, electric actuators, and pneumatic systems. Personnel training and verification procedures ensure that safety protocols are consistently followed during maintenance work. Documentation of isolation procedures helps maintain consistency and provides reference for future maintenance activities.

Personal Protective Equipment Requirements

Maintenance work on angle valve systems often involves exposure to hazardous materials, high pressures, and temperature extremes. Appropriate personal protective equipment selection depends on specific process conditions and potential exposure risks. Respiratory protection may be required when working with toxic or corrosive fluids.

Emergency response procedures should address potential incidents during maintenance activities including fluid releases, equipment failures, and personnel injuries. Communication systems and backup support ensure rapid response to emergency situations. Regular training and drill exercises help maintain emergency response readiness among maintenance personnel.

Documentation and Record Keeping

Maintenance History Tracking

Comprehensive documentation of angle valve maintenance activities provides valuable data for optimizing future maintenance strategies. Detailed records should include inspection findings, repair actions, component replacements, and performance test results. This information helps identify recurring problems and establish optimal maintenance intervals.

Digital maintenance management systems facilitate data storage, retrieval, and analysis of maintenance information. Integration with procurement systems helps manage spare parts inventory and ensures availability of critical components. Trending analysis of maintenance data reveals opportunities for improvement and cost reduction.

Performance Trend Analysis

Regular analysis of angle valve performance trends helps identify gradual deterioration and predict maintenance needs. Statistical analysis of operational data reveals patterns that may not be apparent from individual inspection results. This information supports transition from reactive to predictive maintenance approaches.

Benchmarking performance against similar installations provides context for evaluating maintenance effectiveness. Industry best practices and manufacturer recommendations provide reference points for optimizing maintenance programs. Continuous improvement processes ensure that maintenance strategies evolve with changing technology and operational requirements.

FAQ

How often should angle valve maintenance be performed

Maintenance frequency for angle valve systems depends on operating conditions, service criticality, and manufacturer recommendations. High-cycle applications typically require monthly inspections and quarterly lubrication, while intermittent service valves may need only annual maintenance. Severe service conditions including high temperatures, corrosive fluids, or abrasive materials may require more frequent attention.

What are the signs that an angle valve needs immediate attention

Warning signs requiring immediate angle valve maintenance include external leakage, difficulty operating, unusual noise during operation, and failure to achieve full closure. Changes in flow characteristics or excessive pressure drop may indicate internal problems. Any safety-related symptoms such as uncontrolled flow or structural damage require immediate isolation and repair.

Can angle valve maintenance be performed without system shutdown

Limited maintenance activities such as external lubrication, actuator adjustment, and visual inspection can often be performed during operation. However, internal inspection, seal replacement, and major repairs typically require system isolation and valve removal. Online maintenance capabilities depend on system design, process conditions, and available isolation options.

What specialized tools are needed for angle valve maintenance

Essential tools for angle valve maintenance include torque wrenches for proper assembly, inspection mirrors or endoscopes for internal examination, and pressure testing equipment for performance verification. Specialized pullers and installation tools may be required for seal and bearing replacement. Measurement instruments including calipers and surface finish gauges help assess component condition during inspection.