Home safety encompasses many critical systems, but few are as fundamental as plumbing infrastructure. The quality of plumbing components directly impacts water distribution, pressure regulation, and overall system reliability throughout residential properties. When homeowners invest in superior plumbing solutions, they create a foundation for long-term safety, efficiency, and peace of mind. Understanding the importance of quality plumbing fittings helps property owners make informed decisions that protect both their homes and families from potential water-related hazards.

Understanding Modern Plumbing Distribution Systems

Central Distribution Technology

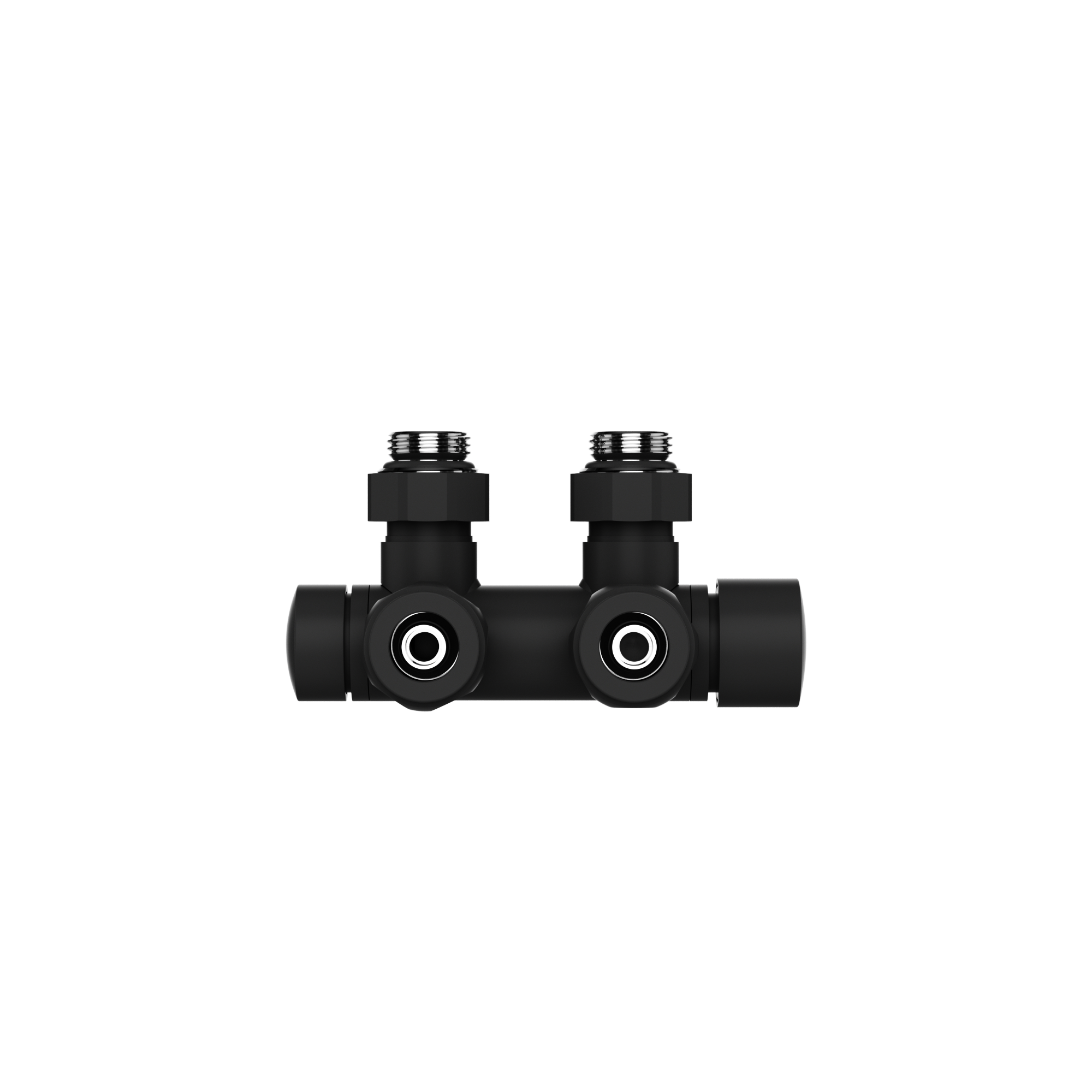

Modern residential plumbing relies heavily on centralized distribution systems that control water flow to multiple fixtures simultaneously. A plumbing manifold serves as the nerve center of these systems, directing water from main supply lines to individual outlets throughout the home. This centralized approach allows for better pressure management, reduced pipe runs, and enhanced control over water distribution. Professional installers recognize that quality manifold systems provide superior performance compared to traditional branching pipe networks.

The engineering behind central distribution involves precise pressure calculations, flow rate optimization, and strategic placement considerations. Quality components ensure consistent water delivery regardless of simultaneous usage patterns. Homeowners benefit from predictable water pressure at every fixture, eliminating the frustration of pressure drops during peak usage periods. This reliability becomes particularly important in multi-story homes where gravity and distance factors can significantly impact water delivery performance.

Component Integration Standards

Integration between various plumbing components requires adherence to strict manufacturing standards and compatibility protocols. Quality fittings are engineered to work seamlessly with different pipe materials, valve types, and fixture connections. This compatibility ensures leak-free joints, proper pressure transmission, and long-term system integrity. Professional plumbers understand that mixing inferior components with quality ones can compromise the entire system's performance and safety.

Material compatibility extends beyond basic connections to include thermal expansion characteristics, chemical resistance, and mechanical stress tolerance. Quality plumbing manifold systems incorporate materials that expand and contract uniformly, preventing joint failures during temperature fluctuations. This engineering consideration becomes crucial in regions with significant seasonal temperature variations where thermal stress can cause inferior fittings to fail prematurely.

Safety Benefits of Premium Plumbing Components

Leak Prevention Technology

Water leaks represent one of the most significant safety hazards in residential plumbing systems, potentially causing structural damage, mold growth, and electrical hazards. Quality plumbing fittings incorporate advanced sealing technologies, precision manufacturing tolerances, and durable materials that significantly reduce leak probability. These components undergo rigorous testing procedures to ensure they can withstand normal operating pressures plus safety margins that account for pressure spikes and system fluctuations.

Professional-grade sealing systems utilize multiple barrier technologies including O-rings, gaskets, and threaded connections that create redundant protection against water escape. Quality plumbing manifold installations feature inspection ports and accessible connection points that allow homeowners and technicians to monitor system integrity over time. This accessibility enables proactive maintenance and early detection of potential issues before they develop into costly emergency repairs.

Pressure Regulation Safety

Proper pressure regulation protects both plumbing fixtures and building occupants from dangerous pressure-related incidents. Quality distribution systems incorporate pressure-limiting devices, expansion chambers, and relief valves that automatically respond to system anomalies. These safety features prevent over-pressurization that could cause fixture damage, pipe bursting, or dangerous spray conditions that might injure building occupants.

Advanced pressure management extends to individual fixture control, allowing homeowners to customize water delivery characteristics for different applications. Quality plumbing manifold systems enable zone-specific pressure adjustments, accommodating varying fixture requirements while maintaining overall system safety. This granular control proves particularly valuable in homes with mixed fixture types, specialty appliances, or accessibility considerations that require specific pressure ranges.

Long-Term Performance and Reliability

Material Durability Standards

The longevity of plumbing systems depends heavily on material selection and manufacturing quality of core components. Premium fittings utilize corrosion-resistant alloys, high-grade plastics, and composite materials that maintain structural integrity throughout decades of continuous service. These materials resist common failure modes including galvanic corrosion, chemical degradation, and mechanical wear that typically affect inferior components within just a few years of installation.

Quality control processes ensure consistent material properties, dimensional accuracy, and surface finish characteristics that contribute to extended service life. Manufacturing standards for professional plumbing manifold components include stress testing, chemical resistance evaluation, and accelerated aging protocols that simulate years of real-world usage. This comprehensive testing approach gives homeowners confidence that their investment will provide reliable service throughout the expected system lifespan.

Maintenance Accessibility Features

Quality plumbing installations prioritize maintenance accessibility, incorporating design features that simplify routine service and emergency repairs. Accessible shutoff valves, removable inspection covers, and standardized connection interfaces allow technicians to perform maintenance tasks efficiently without system-wide shutdowns. This accessibility reduces maintenance costs and minimizes service disruption for building occupants.

Professional installation practices emphasize proper component spacing, clear labeling systems, and documentation that supports long-term maintenance programs. Quality plumbing manifold systems include integrated mounting hardware, protective enclosures, and clear identification markings that facilitate quick diagnosis and repair activities. These features prove invaluable during emergency situations where rapid system restoration is critical for building safety and occupant comfort.

Economic Advantages of Quality Plumbing Investments

Installation Efficiency Benefits

Quality plumbing components streamline installation processes through precision manufacturing, clear documentation, and standardized connection interfaces. Professional installers can complete projects more efficiently when working with components that fit properly, include necessary hardware, and provide clear installation guidelines. This efficiency translates to reduced labor costs and faster project completion times for homeowners.

Standardization benefits extend to tool requirements, installation techniques, and testing procedures that professional plumbers use consistently across different projects. Quality plumbing manifold systems utilize common connection methods and standard tool interfaces that minimize specialized equipment requirements. This standardization reduces installation complexity and potential for errors that could compromise system performance or safety.

Operational Cost Considerations

Energy efficiency represents a significant operational advantage of quality plumbing distribution systems. Efficient water delivery reduces pump operating time, minimizes heat loss in hot water lines, and enables precise flow control that eliminates waste. Quality components maintain their efficiency characteristics throughout their service life, providing consistent operational savings that help offset initial investment costs.

Water conservation features built into premium plumbing manifold systems include flow regulation, leak detection capabilities, and zone-specific control that allows homeowners to optimize usage patterns. These features become increasingly valuable as water costs rise and conservation regulations become more stringent. Quality systems provide the flexibility to adapt to changing usage requirements without major system modifications.

Professional Installation and System Integration

Technical Expertise Requirements

Proper installation of quality plumbing systems requires specialized knowledge of hydraulic principles, material compatibility, and local building codes. Professional plumbers understand pressure calculations, pipe sizing methodology, and integration requirements that ensure optimal system performance. Their expertise prevents common installation errors that could compromise safety or efficiency regardless of component quality.

Code compliance represents a critical aspect of professional installation that affects both safety and legal liability. Quality plumbing manifold installations must meet specific requirements for accessibility, pressure testing, and documentation that demonstrate compliance with local regulations. Professional installers provide necessary permits, inspection coordination, and warranty documentation that protects homeowners' investments.

System Testing and Commissioning

Comprehensive system testing validates proper installation and identifies potential issues before systems enter regular service. Professional testing procedures include pressure testing, flow verification, and functional checks of all control devices and safety features. This thorough approach ensures that quality components perform as designed and that system integration meets all performance specifications.

Commissioning documentation provides baseline performance data that supports future maintenance activities and warranty claims. Quality plumbing manifold systems include detailed specifications, performance curves, and recommended maintenance schedules that guide long-term system management. This documentation proves invaluable for troubleshooting, system modifications, and insurance claims related to plumbing system performance.

FAQ

What makes a plumbing manifold superior to traditional pipe branching systems

A plumbing manifold provides centralized water distribution that eliminates the pressure variations common in traditional branching systems. This technology delivers consistent water pressure to all fixtures simultaneously, reduces the total length of piping required, and enables individual fixture control through dedicated supply lines. Quality manifold systems also simplify maintenance access and provide better leak isolation capabilities compared to interconnected pipe networks.

How often should quality plumbing fittings be inspected or maintained

Quality plumbing fittings typically require annual visual inspections to check for signs of leakage, corrosion, or mechanical damage. Professional maintenance should be performed every three to five years, including pressure testing, seal replacement, and functional verification of control devices. However, quality components are designed for minimal maintenance requirements, with many systems providing decades of reliable service with only routine inspections and occasional seal replacement.

What are the warning signs that indicate plumbing fittings need replacement

Key warning signs include visible water stains around connections, decreased water pressure at fixtures, unusual sounds during water usage, and visible corrosion or mineral deposits on fittings. Other indicators include fluctuating water pressure, delayed fixture response, and increased utility bills that might indicate hidden leaks. Quality plumbing manifold systems often include monitoring capabilities that provide early warning of potential issues before they become serious problems.

Can homeowners install quality plumbing manifold systems themselves

While some experienced homeowners may have the skills necessary for basic plumbing work, manifold system installation typically requires professional expertise due to code requirements, pressure testing needs, and integration complexities. Professional installation ensures proper sizing calculations, code compliance, warranty validity, and optimal system performance. Many manufacturers require professional installation to maintain warranty coverage, making professional installation both a safety and financial consideration for most homeowners.