Modern heating systems face numerous challenges that can significantly impact their performance, efficiency, and lifespan. Among the most effective solutions available today, a boiler magnetic filter stands out as an essential component for protecting your heating infrastructure from harmful debris and contaminants. This innovative technology has revolutionized how we approach system maintenance and protection, offering homeowners and commercial property managers a reliable method to safeguard their heating investments while maximizing operational efficiency and reducing long-term costs.

Understanding Boiler Magnetic Filter Technology

Core Principles of Magnetic Filtration

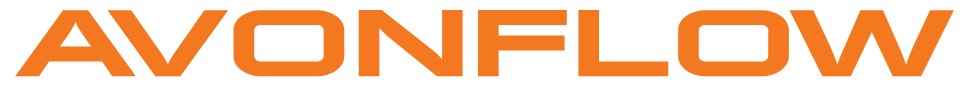

The fundamental operation of a boiler magnetic filter relies on powerful magnetic fields that capture ferrous particles circulating within heating systems. These devices utilize strategically positioned rare earth magnets to create strong magnetic zones that attract iron oxide particles, rust flakes, and other metallic debris before they can cause damage to sensitive components. The magnetic attraction process occurs continuously as heated water flows through the filter housing, ensuring constant protection without requiring electrical power or frequent maintenance interventions.

Advanced magnetic filtration systems incorporate multiple magnetic poles arranged in specific configurations to maximize particle capture efficiency. The design typically features a cylindrical housing with internal magnetic cores that create turbulent flow patterns, forcing contaminated water through concentrated magnetic fields. This approach ensures that even microscopic ferrous particles cannot escape the filtration zone, providing comprehensive protection for boilers, heat exchangers, and circulating pumps throughout the entire heating network.

Magnetic Field Strength and Particle Capture

Professional-grade boiler magnetic filter units employ neodymium magnets capable of generating magnetic field strengths exceeding 10,000 Gauss, creating powerful attraction forces that capture particles as small as 5 microns. This level of filtration precision ensures that even the finest iron oxide particles cannot circulate through the system, preventing gradual accumulation in narrow passages, valve seats, and heat exchanger surfaces. The magnetic strength remains constant over extended periods, providing reliable filtration performance without degradation or power consumption requirements.

The effectiveness of magnetic particle capture depends significantly on water flow velocity and residence time within the magnetic field zone. Optimal filter designs balance flow resistance with contact time, ensuring adequate particle exposure to magnetic forces while maintaining sufficient circulation rates for proper system operation. Modern units incorporate flow directors and internal baffles that create controlled turbulence patterns, enhancing particle-magnet interaction without causing excessive pressure drops that could affect system performance.

Benefits of Installing Magnetic Filters

System Protection and Longevity

Installing a high-quality boiler magnetic filter provides comprehensive protection against corrosion-related damage that commonly affects heating systems over time. Ferrous particles suspended in circulating water act as abrasive agents that gradually wear down pump impellers, valve components, and heat exchanger surfaces, leading to reduced efficiency and premature component failure. By removing these harmful particles before they can cause damage, magnetic filtration extends equipment lifespan significantly while maintaining optimal performance characteristics.

The protective benefits extend beyond mechanical components to include preservation of water quality and system chemistry balance. Accumulated iron oxide particles can alter water pH levels and promote further corrosion reactions, creating a cascading effect that accelerates system deterioration. Magnetic filtration breaks this destructive cycle by continuously removing corrosion products, maintaining stable water chemistry conditions that support long-term system integrity and reliable operation throughout the heating season.

Energy Efficiency Improvements

Clean heating systems operate significantly more efficiently than contaminated ones, with studies showing that proper filtration can improve overall system efficiency by 6-8% annually. A well-maintained boiler magnetic filter ensures optimal heat transfer rates by preventing particle buildup on critical surfaces, allowing boilers to achieve target temperatures more quickly while consuming less fuel. This efficiency improvement translates directly into reduced energy costs and lower carbon emissions, making magnetic filtration an environmentally responsible choice for heating system operators.

The energy savings compound over time as magnetic filtration prevents gradual efficiency degradation that typically occurs in unprotected systems. Without proper filtration, accumulated debris creates insulating layers on heat transfer surfaces, forcing boilers to work harder and consume more fuel to maintain desired temperatures. Magnetic filters eliminate this problem by maintaining clean surfaces throughout the system lifecycle, ensuring consistent performance and predictable operating costs for property owners and facility managers.

Installation and Integration Considerations

System Compatibility and Sizing

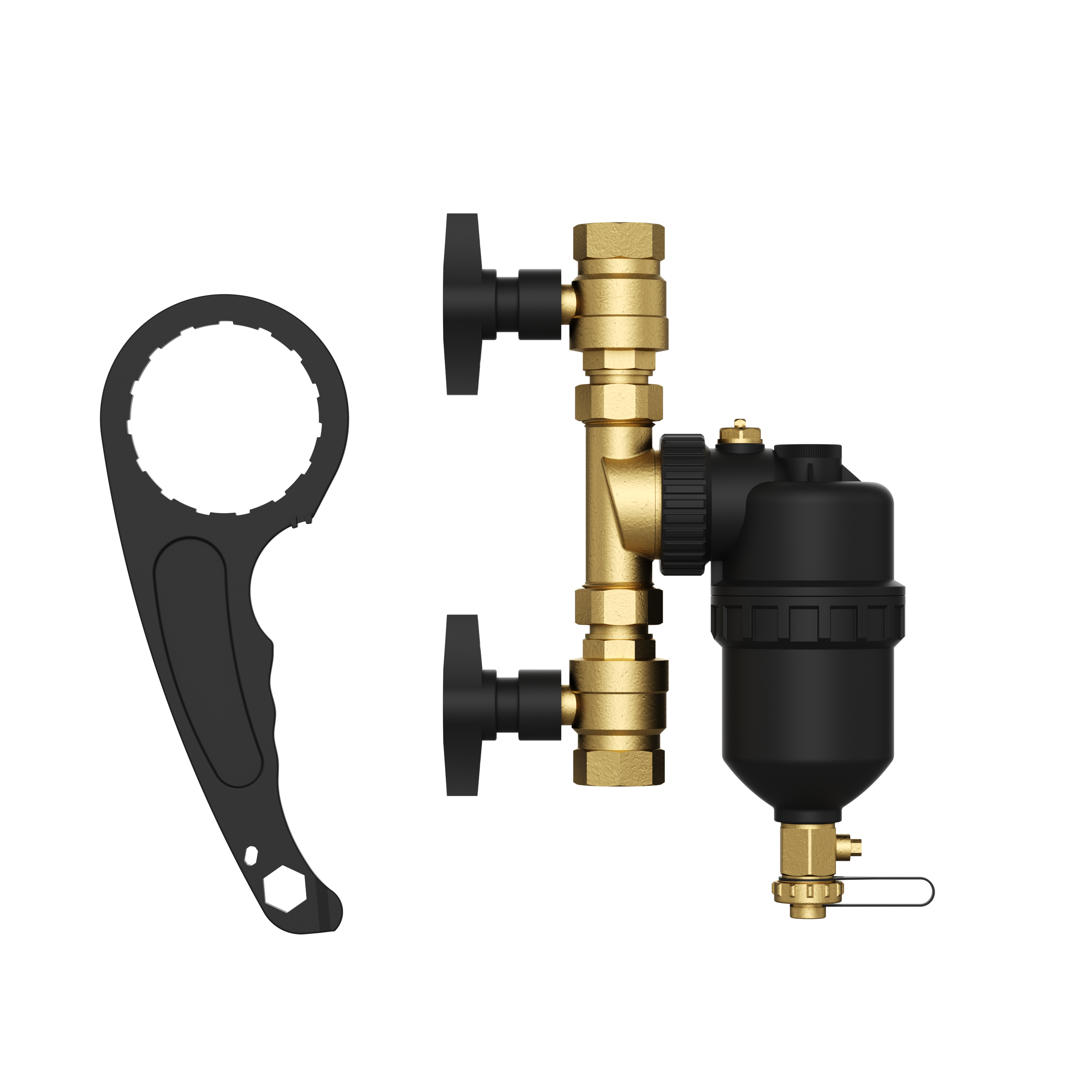

Proper boiler magnetic filter selection requires careful consideration of system flow rates, pipe dimensions, and installation space constraints to ensure optimal performance and seamless integration. Most residential and light commercial applications utilize filters sized for pipe diameters ranging from 15mm to 35mm, with flow capacities designed to match typical circulation pump specifications. The filter housing dimensions must accommodate both the magnetic core assembly and adequate service access for periodic maintenance and debris removal procedures.

Professional installation typically involves integration into the return line before the boiler inlet, where water temperatures remain moderate and particle concentrations are highest due to circulation through the entire system network. This positioning strategy maximizes filtration effectiveness while protecting the magnetic components from excessive heat that could affect magnetic field strength. Proper installation includes isolation valves on both sides of the filter to facilitate maintenance operations without system shutdown requirements.

Maintenance Requirements and Procedures

Regular maintenance of a boiler magnetic filter involves periodic cleaning of accumulated magnetic debris to maintain optimal filtration capacity and prevent flow restrictions. The maintenance frequency depends on system age, water quality, and contamination levels, with newer systems typically requiring cleaning every 6-12 months and older systems needing more frequent attention. The cleaning process involves isolating the filter, removing the magnetic core assembly, and thoroughly cleaning accumulated particles using appropriate cleaning solutions and procedures.

Modern filter designs incorporate easy-access features that simplify maintenance procedures and reduce service time requirements. Quick-release mechanisms allow rapid removal of magnetic cores without tools, while clear housing materials enable visual inspection of debris accumulation levels. Professional technicians can complete routine maintenance in 15-20 minutes, making magnetic filtration a low-maintenance solution that provides maximum protection benefits with minimal operational disruption or ongoing service costs.

Performance Monitoring and Optimization

Debris Analysis and System Health Assessment

The debris collected by a boiler magnetic filter provides valuable diagnostic information about overall system health and potential problems requiring attention. Regular analysis of particle types, quantities, and accumulation rates helps identify developing issues such as accelerated corrosion, component wear, or water chemistry imbalances before they cause serious damage. This predictive maintenance capability allows property owners to address problems proactively, preventing costly repairs and system failures.

Professional service technicians utilize standardized debris analysis procedures to evaluate system condition and recommend appropriate corrective actions. Heavy particle accumulation may indicate inadequate water treatment, while specific particle types can pinpoint the source of corrosion problems within the system network. This diagnostic capability makes magnetic filtration an essential tool for comprehensive system management and optimization strategies that maximize equipment lifespan and performance reliability.

Integration with Water Treatment Programs

Effective boiler magnetic filter performance requires coordination with comprehensive water treatment programs that address chemical corrosion prevention and water quality management. Magnetic filtration removes the physical products of corrosion but does not prevent the underlying chemical processes that create these particles. Combined treatment approaches that include chemical inhibitors, pH control, and magnetic filtration provide superior protection compared to single-technology solutions.

Professional water treatment specialists recommend integrated programs that utilize magnetic filtration as the primary particle removal mechanism while employing chemical treatments to prevent new corrosion formation. This synergistic approach maximizes system protection while minimizing treatment costs and maintenance requirements. Regular monitoring of both debris accumulation and water chemistry parameters ensures optimal performance from all system protection components throughout the heating season.

Economic Analysis and Return on Investment

Cost-Benefit Evaluation Framework

The economic benefits of boiler magnetic filter installation extend far beyond the initial purchase price, encompassing reduced maintenance costs, improved energy efficiency, and extended equipment lifespan. Professional cost-benefit analyses typically show complete return on investment within 2-3 years for residential systems and 12-18 months for commercial installations. These calculations include quantified savings from reduced service calls, lower energy consumption, and delayed equipment replacement requirements that result from proper system protection.

Long-term financial benefits continue accumulating throughout the filter's operational lifetime, which typically exceeds 15-20 years with proper maintenance. The cumulative savings from improved efficiency, reduced repairs, and extended equipment life often exceed the initial filter investment by factors of 10-15 times over a typical system lifecycle. This exceptional return on investment makes magnetic filtration one of the most cost-effective system improvements available to heating system operators seeking to optimize operational costs and reliability.

Insurance and Warranty Considerations

Many equipment manufacturers and insurance providers recognize the protective benefits of boiler magnetic filter installation by offering enhanced warranty coverage and reduced insurance premiums for properly protected systems. Some boiler warranties specifically require magnetic filtration to maintain coverage validity, while others provide extended warranty periods when filters are installed according to manufacturer specifications. These additional benefits further improve the economic case for magnetic filtration investment.

Insurance companies increasingly offer premium discounts for commercial properties equipped with comprehensive system protection measures including magnetic filtration. The reduced claim frequency and severity associated with properly protected heating systems makes them attractive risks for insurance underwriters. Property owners should consult with their insurance providers to understand available incentives and requirements for maintaining coverage on heating system equipment and related property damage risks.

FAQ

How often should a boiler magnetic filter be cleaned

The cleaning frequency for a boiler magnetic filter depends on system age, water quality, and contamination levels, but most residential systems require cleaning every 6-12 months during the first few years of operation. Older systems or those with significant existing contamination may need more frequent attention initially, with cleaning intervals extending as debris levels decrease over time. Professional technicians can assess accumulation rates during routine service visits and recommend optimal maintenance schedules based on specific system conditions and performance requirements.

Can magnetic filters be installed on existing heating systems

Yes, boiler magnetic filter units can be retrofitted to virtually any existing heating system with appropriate pipe connections and adequate installation space. The installation process typically involves cutting into the return line and installing the filter housing with appropriate fittings and isolation valves. Professional installation ensures proper sizing, positioning, and integration with existing system components while maintaining safe and reliable operation. Most installations can be completed in 2-4 hours with minimal system downtime.

Do magnetic filters affect water pressure or flow rates

Properly sized and installed boiler magnetic filter units have minimal impact on system pressure or flow rates when maintained according to manufacturer recommendations. Quality filters are designed with optimized flow passages that minimize pressure drops while maximizing magnetic field exposure. However, accumulated debris can restrict flow if cleaning intervals are extended beyond recommended schedules, making regular maintenance essential for maintaining optimal hydraulic performance throughout the system network.

What types of particles do magnetic filters capture

Boiler magnetic filter systems primarily capture ferrous particles including iron oxide (rust), scale deposits, and metallic debris generated by system corrosion and component wear. The powerful magnetic fields effectively remove particles ranging from large rust flakes down to microscopic iron oxide particles as small as 5 microns. While magnetic filters excel at removing ferrous materials, they do not capture non-magnetic particles such as calcium deposits or organic matter, which require different filtration or treatment approaches for complete system protection.