Understanding the Critical Role of Angle Valves in Modern Plumbing

In the complex world of plumbing and water control systems, angle valves stand as essential components that often go unnoticed yet play a crucial role in maintaining efficient water flow and control. These specialized valves, distinguished by their unique L-shaped design, serve as the primary gatekeepers of water flow in countless residential and commercial applications. Their strategic placement and reliable functionality make them indispensable in modern plumbing infrastructure.

The significance of an angle valve extends far beyond its simple appearance. These compact yet powerful devices enable precise control over water flow, prevent backflow issues, and provide easy access for maintenance and emergency shutoffs. As water management becomes increasingly critical in today's resource-conscious world, understanding the importance of angle valves has never been more relevant.

The Engineering Marvel Behind Angle Valve Design

Structural Components and Their Functions

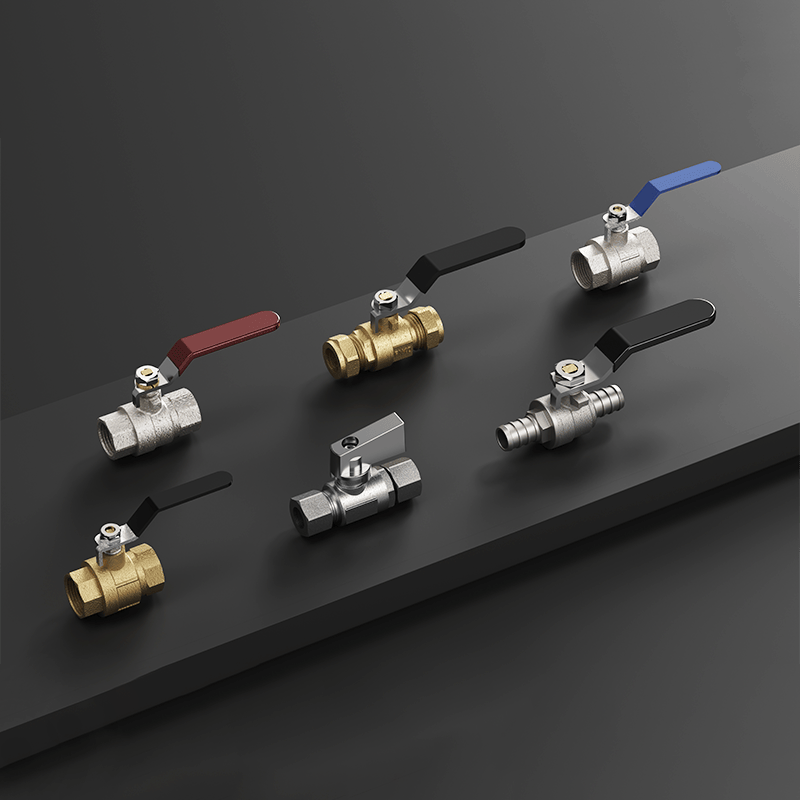

At the heart of every angle valve lies a sophisticated engineering design that combines durability with precision. The main body, typically crafted from brass or chrome-plated materials, houses the internal mechanisms that control water flow. The valve stem, equipped with reliable sealing components, ensures smooth operation while preventing leaks. The compression mechanism, whether traditional or ceramic disc-based, provides the necessary control over water flow.

Modern angle valves incorporate advanced features such as quarter-turn operation, ceramic disc cartridges, and anti-leak seals. These innovations have significantly improved their reliability and longevity, making them more efficient than ever before. The precision engineering extends to the connection points, which are designed to maintain consistent pressure and prevent water hammer effects.

Material Science and Durability

The choice of materials in angle valve construction directly impacts their performance and lifespan. High-grade brass remains the preferred material for the main body due to its excellent corrosion resistance and durability. The valve seats and seals utilize advanced synthetic materials that withstand repeated use while maintaining their integrity. Modern manufacturing processes ensure these components meet strict quality standards for long-term reliability.

Surface treatments such as chrome plating or brushed nickel finishes not only enhance aesthetic appeal but also provide additional protection against environmental factors. The development of lead-free brass alloys has made angle valves safer for potable water applications, meeting increasingly stringent environmental and health regulations.

Installation and Integration Considerations

Strategic Placement for Optimal Performance

The effectiveness of an angle valve largely depends on its proper installation and strategic placement within the water system. Professional installers carefully consider factors such as accessibility, clearance for operation, and protection from physical damage. The valve's orientation must allow for easy operation while maintaining the integrity of the plumbing system's design.

Installation requirements often vary based on the specific application and local building codes. Proper support of connected pipes, appropriate use of thread sealants, and correct torque application during installation are crucial factors that influence long-term performance. The growing trend toward modular plumbing systems has made angle valve installation more standardized and efficient.

System Integration Best Practices

Successful integration of angle valves into water control systems requires careful attention to compatibility and flow requirements. System designers must consider factors such as pressure ratings, temperature limitations, and flow capacity when selecting appropriate angle valves. The integration process often involves careful coordination between plumbing fixtures, supply lines, and control mechanisms.

Modern building management systems increasingly incorporate smart angle valves that can be monitored and controlled remotely. This integration enables better water management and early detection of potential issues. The trend toward sustainable building practices has also influenced how angle valves are integrated into water-efficient systems.

Maintenance and Troubleshooting Essentials

Preventive Maintenance Protocols

Regular maintenance of angle valves is crucial for ensuring their continued reliable operation. A comprehensive maintenance program includes periodic inspection of visible components, testing of valve operation, and assessment of sealing effectiveness. Professional maintenance technicians follow established protocols to identify potential issues before they become serious problems.

The maintenance schedule typically includes checking for mineral deposits, lubricating moving parts when necessary, and verifying proper operation of the shut-off mechanism. Advanced maintenance programs may utilize predictive techniques such as pressure testing and leak detection to optimize valve performance and longevity.

Common Issues and Solutions

Despite their robust design, angle valves can encounter operational issues that require attention. Common problems include leaking from the stem or bonnet, difficult operation due to mineral buildup, and wear of sealing components. Understanding these issues and their solutions is essential for maintaining system reliability.

Most problems can be resolved through proper diagnosis and appropriate corrective actions. This might involve replacing worn seals, cleaning mineral deposits, or in some cases, replacing the entire valve assembly. The availability of standardized repair kits and clear maintenance procedures makes most repairs straightforward for qualified professionals.

Future Trends and Innovations

Smart Technology Integration

The future of angle valves is being shaped by advances in smart technology and automation. Manufacturers are developing valves with integrated sensors that can monitor flow rates, pressure levels, and operational status. These smart angle valves can communicate with building management systems, enabling proactive maintenance and improved water management.

The integration of Internet of Things (IoT) capabilities allows for remote monitoring and control, making it possible to detect and respond to issues before they cause significant problems. These advances are particularly valuable in large commercial buildings and industrial applications where water system reliability is critical.

Sustainable Design Developments

Environmental considerations are driving innovations in angle valve design and materials. Manufacturers are developing more efficient designs that minimize water waste and reduce energy consumption. New materials and manufacturing processes are being explored to create more sustainable products while maintaining high performance standards.

The trend toward water conservation has led to the development of angle valves with improved flow control capabilities and better pressure regulation. These innovations help building operators meet sustainability goals while maintaining necessary system performance.

Frequently Asked Questions

How often should angle valves be maintained?

Regular maintenance of angle valves should be performed annually, with visual inspections conducted quarterly. However, high-use applications may require more frequent maintenance. Professional inspection should include testing valve operation, checking for leaks, and assessing overall condition.

What are the signs that an angle valve needs replacement?

Key indicators include persistent leaks that cannot be resolved through maintenance, difficulty in operation, visible corrosion or damage, and age beyond the manufacturer's recommended service life. Strange noises during operation or inconsistent water flow may also signal the need for replacement.

Can angle valves be upgraded to smart versions?

Yes, many existing angle valve installations can be upgraded with smart monitoring devices or replaced with integrated smart valve systems. These upgrades typically require professional installation and may need additional infrastructure for communication and control capabilities.