Understanding the Critical Role of Angle Valves in Bathroom Plumbing

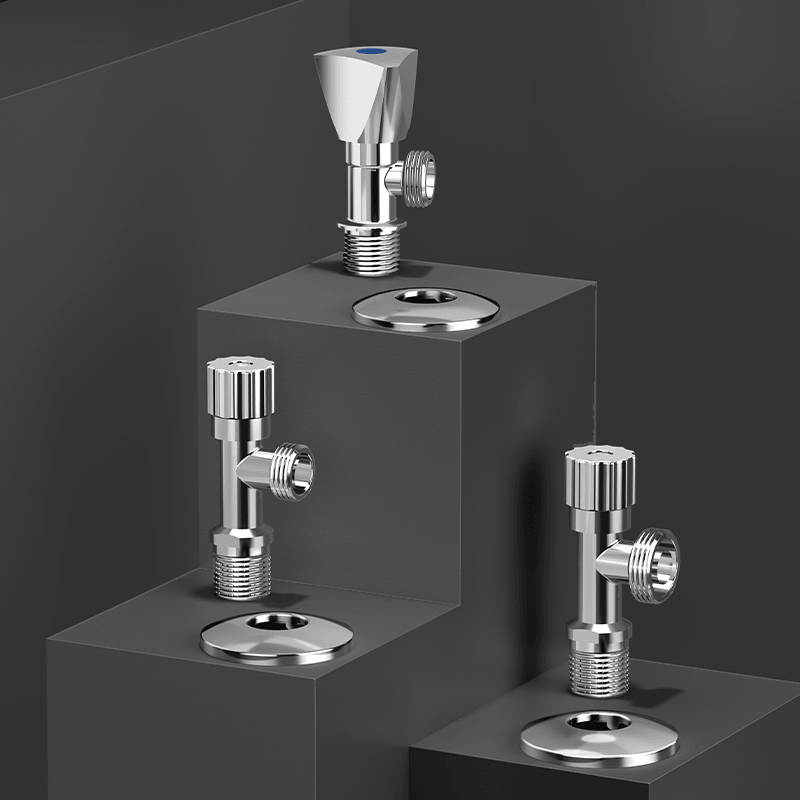

A well-functioning bathroom relies heavily on proper plumbing fixtures, with angle valves being one of the most essential components. These small but crucial devices control water flow to your fixtures, providing both convenience and safety. Whether you're renovating your bathroom or replacing old fixtures, selecting the right angle valve ensures optimal performance and longevity of your plumbing system.

Modern angle valves come in various materials, sizes, and configurations, each designed to meet specific plumbing requirements. Understanding these differences can significantly impact your bathroom's functionality and prevent potential issues down the line. Let's explore everything you need to know about choosing the perfect angle valve for your bathroom setup.

Key Components and Materials of Quality Angle Valves

Premium Material Choices for Durability

The durability of an angle valve largely depends on its construction material. Brass remains the most popular choice for angle valve bodies due to its excellent corrosion resistance and long-lasting performance. Chrome-plated brass offers both functionality and aesthetic appeal, while stainless steel variants provide superior resistance to harsh water conditions.

Some manufacturers also offer lead-free brass options, particularly important for drinking water applications. These specialized materials ensure compliance with current safety standards while maintaining the robust performance expected from quality angle valves.

Internal Components That Matter

The internal mechanism of an angle valve is crucial for its operation. Ceramic disc cartridges have become the industry standard, replacing older rubber washers due to their superior durability and smooth operation. These cartridges provide consistent performance and require minimal maintenance throughout their lifetime.

Quality angle valves also feature precision-engineered stems and bonnets, ensuring leak-free operation even under varying water pressures. The inclusion of high-grade O-rings and seals further enhances reliability and prevents water seepage.

Sizing and Connection Types for Perfect Installation

Standard Dimensions and Compatibility

Selecting the correct size angle valve is crucial for proper installation and function. Common inlet sizes include 1/2 inch and 3/8 inch connections, while outlet sizes typically range from 3/8 inch to 1/4 inch. Understanding your plumbing system's requirements ensures compatibility and prevents installation issues.

It's essential to consider both the inlet and outlet configurations when selecting an angle valve. Many modern fixtures require specific connection types, and choosing the wrong size can lead to additional costs and complications during installation.

Connection Methods and Their Applications

Different connection types serve various installation scenarios. Compression fittings offer simple installation and reliability for copper or plastic supply lines. Threaded connections provide secure attachment for metal pipes, while quick-connect systems enable tool-free installation in compatible setups.

Professional plumbers often recommend specific connection types based on local building codes and water pressure conditions. Understanding these requirements helps ensure a proper and code-compliant installation.

Design Features for Enhanced Performance

Flow Control and Pressure Management

Modern angle valves incorporate sophisticated flow control mechanisms to manage water pressure effectively. Quarter-turn operation has become increasingly popular, offering quick shut-off capability and precise flow adjustment. Some models include built-in pressure regulators to protect connected fixtures from excessive water pressure.

Advanced angle valves may feature multi-turn stems that allow for more precise flow adjustment, particularly beneficial in applications requiring careful water flow management. These features contribute to both user convenience and system longevity.

Maintenance and Accessibility Features

Easy maintenance access is a crucial design consideration in quality angle valves. Removable handles and serviceable cartridges allow for simple repairs without requiring complete valve replacement. Some models include integrated filters to protect downstream fixtures from debris, extending the life of connected equipment.

Look for angle valves with clearly marked hot and cold indicators and ergonomic handles that provide comfortable operation. These user-friendly features enhance daily use and simplify maintenance procedures.

Installation Considerations and Best Practices

Professional Installation Guidelines

Proper installation ensures optimal performance and longevity of angle valves. Always clean and prepare connection points thoroughly before installation. Use appropriate thread sealant or plumber's tape on threaded connections to prevent leaks. When tightening connections, avoid over-torquing, which can damage threads or compromise seals.

Professional installers recommend pressure testing new installations before closing walls or completing finish work. This step helps identify potential issues early and ensures long-term reliability of the plumbing system.

Common Installation Pitfalls to Avoid

Several common mistakes can compromise angle valve performance. Mixing different metals without proper dielectric unions can lead to galvanic corrosion. Failing to properly support supply lines can stress valve connections and cause leaks over time. Additionally, using the wrong tools or excessive force during installation can damage valve components.

Taking time to properly align and secure angle valves during installation prevents future problems and ensures smooth operation. Regular inspection of visible connections helps identify potential issues before they become serious problems.

Frequently Asked Questions

How Often Should Angle Valves Be Replaced?

Quality angle valves typically last 15-20 years with proper maintenance. However, replacement may be necessary sooner if you notice signs of corrosion, persistent leaks, or difficulty in operation. Regular inspection and maintenance can significantly extend their service life.

Can I Install an Angle Valve Myself?

While basic angle valve installation is possible for experienced DIY enthusiasts, professional installation is recommended to ensure proper function and compliance with local plumbing codes. Improper installation can lead to leaks, water damage, and potential warranty issues.

What Signs Indicate an Angle Valve Needs Replacement?

Watch for signs such as visible corrosion, mineral buildup, leaking around the stem or connections, difficult operation, or inconsistent water flow. If you notice any of these issues, it's best to replace the valve before it fails completely.

Are All Angle Valves Compatible with Any Plumbing System?

Not all angle valves are universally compatible. Factors such as pipe material, water pressure, local building codes, and fixture requirements determine the appropriate type of angle valve. Always verify compatibility with your specific plumbing system before purchase and installation.